Engineered

Class Chains

Chain Resources

Contact Us

Combination Chains

- Overview

- Material

- Assembly

- Interchangeability

- Application

- Operation

- Specifications

Combination chains are made of cast block links and steel sidebars alternately spaced. The N combination chains have pear-shaped barrels to provide additional metal where the chain engages the sprocket teeth to increase the service life of the chain. Combination chains are well suited for abrasive, gritty or corrosive materials and are a less expensive option to their all steel counterparts (HSB).

Industries

The cast links are high grade copper bearing Duramal with holes smoothly cored for a close fit over the pins. Duramal chains have heat treated pins with Duramal block links. Super Duramal chains have heat treated pins and sidebars with Duramal block links. Chains are also available with block links of file hard Duramal.

Riveted construction is recommended for wood yards and sawmills. Cottered construction is recommended for elevators and conveyors. Riveted or cottered construction must be specified. Chain pins will be alternating, except on C55, N77, N131 and C188 chains.

Combination chains are interchangeable with other standard makes of corresponding sizes and numbers.

Combination chain is well suited for the handling of stone, cement, gravel and other abrasive materials. It is used extensively in elevating and conveying service where a strong durable, yet inexpensive, chain is required.

Maximum chain speed depends upon size of sprockets. For Conveyor Service see Table 2, Section A.

Combination Chains Product Specifications

Product Information

Dimensions are in inches unless otherwise noted.

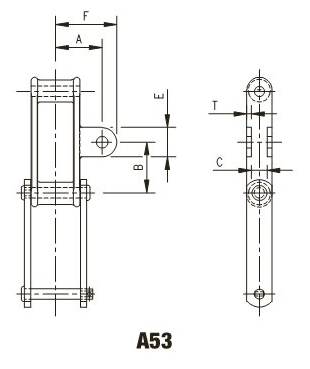

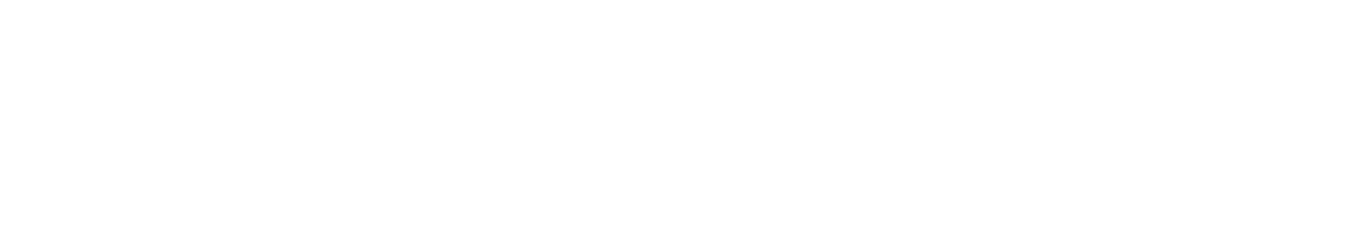

Dimensions:

Product Chart:

Swipe to See More

| Chain No. | Average Pitch Inches | Approx. Links in 10 feet | Average Weight Per Ft. Lbs. | Average Ultimate Strength in Lbs. | Rated Working Load in Lbs. | Dimensions in Inches | Common Attachment Numbers | |||||||||

| Barrel Length | Sidebar Width | Max. Spkt. Width | Pin Dia. | Nominal Barell Dia. | To Cotter End | To Head or Rivet End | Sidebar Thk. | |||||||||

| Duramal | Duramal | X | F | A | D | H | K | J | T | Block Link | Sidebar | |||||

| C55 | 1.631 | 74 | 2.0 | 11,250 | 1,370 | 1 7/32 | 3/4 | 11/16 | 3/8 | 23/32 | 1 1/16 | 1 | 3/16 | |||

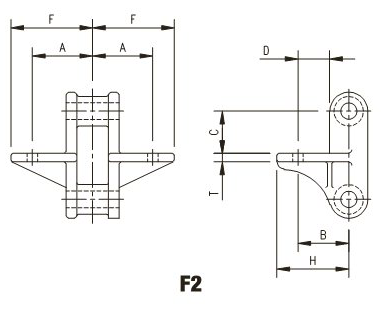

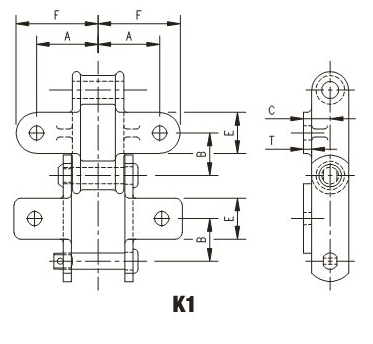

| N77 | 2.308 | 52 | 2.2 | 13,750 | 1,640 | 1 1/4 | 7/8 | 11/16 | 7/16 | 23/32 | 1 5/32 | 1 | 3/16 | F2 | K1 | |

| N102B | 4.000 | 30 | 6.7 | 30,000 | 5,000 | 2 7/8 | 1 1/2 | 1 15/16 | 5/8 | 1 | 2 3/16 | 2 1/16 | 3/8 | K2 | K2, S1 | |

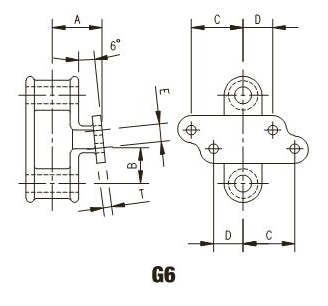

| N102 1/2 | 4.040 | 30 | 9.4 | 45,000 | 6,600 | 2 15/16 | 1 3/4 | 2 | 3/4 | 1 3/8 | 2 3/8 | 2 1/8 | 3/8 | A42, F2, G6, K2, K3, K22 | A42, F2, K2, K3, K22, S1 | |

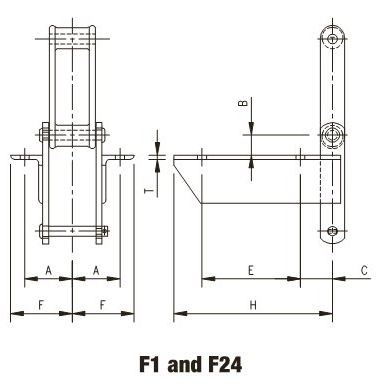

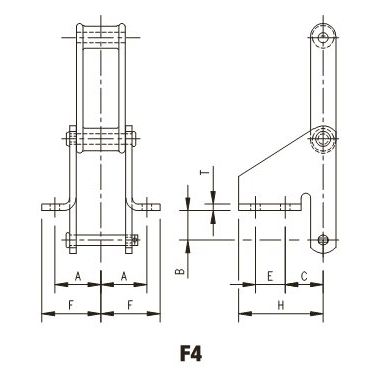

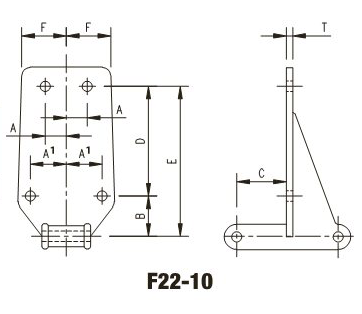

| N110 | 6.000 | 20 | 6.0 | 30,000 | 5,000 | 2 7/8 | 1 1/2 | 1 15/16 | 5/8 | 1 1/4 | 2 3/16 | 2 1/16 | 3/8 | A53, F22-10, K2 | A42, F1, F2, F4, F24, K2 | |

| N111 | 4.760 | 25 | 9.7 | 45,000 | 7,500 | 3 3/8 | 1 3/4 | 2 3/8 | 3/4 | 1 7/16 | 2 19/32 | 2 11/32 | 3/8 | F2, K2, K22 | F2, K1, K2, K22, S1 | |

| N111SPC | 4.760 7.240 | 20 | 8.5 | 45,000 | 7,500 | 3 3/8 | 1 3/4 | 2 3/8 | 3/4 | 1 7/16 | 2 19/32 | 2 11/32 | 3/8 | F2, K2 | K2 | |

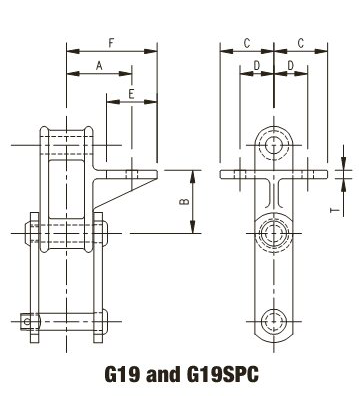

| N131 | 3.075 | 39 | 6.5 | 30,000 | 3,750 | 2 | 1 1/2 | 1 1/8 | 5/8 | 1 1/4 | 1 13/16 | 1 5/8 | 3/8 | F2, G6, K1, K2 | A42, G19, K1, K2, S1 | |

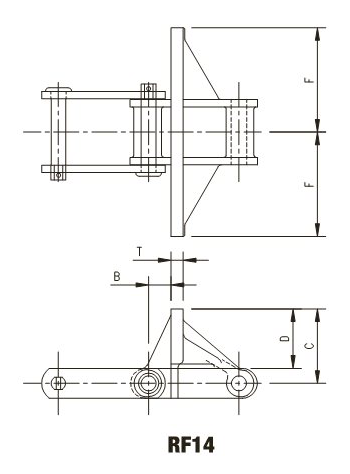

| N132 | 6.050 | 20 | 14.4 | 62,500 | 10,400 | 4 3/8 | 2 | 3 1/8 | 1 | 1 3/4 | 3 7/32 | 3 1/32 | 1/2 | K2, RF14 | F2, K2, S1 | |

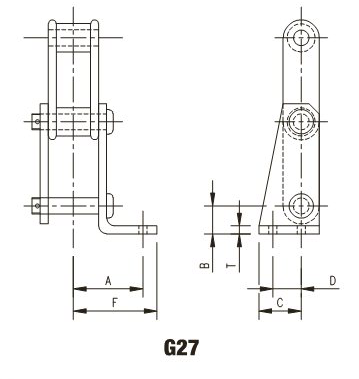

| C188 | 2.609 | 46 | 3.6 | 17,500 | 2,340 | 1 9/16 | 1 1/8 | 15/16 | 1/2 | 7/8 | 1 11/32 | 1 7/32 | 1/4 | F2, G6, G19, G19SPC, K1, K2, K22 | A22, A42, G27, K1, K2, K1/K2, K22, S1 | |

Dimensions are in inches unless otherwise noted.

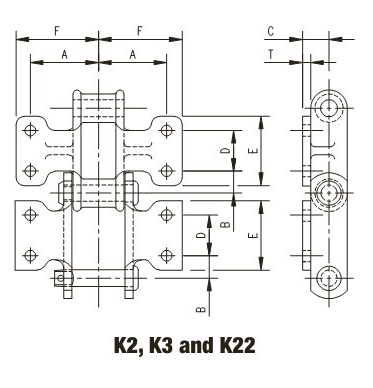

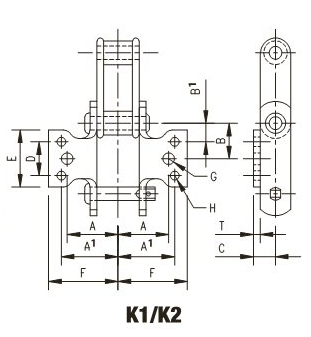

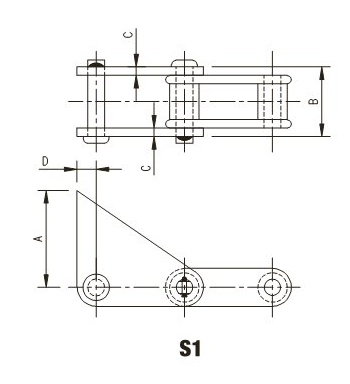

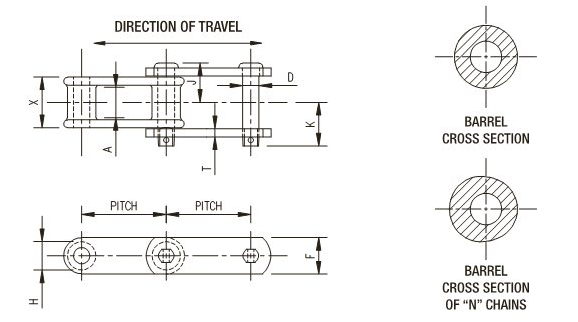

Select an attachment below:

Click to view 3D

Click to view 3D

| Chain No. | A | B | E | F | T | Weight Per Foot-Lbs. | Bolt Size | |

|---|---|---|---|---|---|---|---|---|

| C188 | 1 7/16 | 1 5/16 | 1 1/4 | 2 1/16 | 3/8 | Ñ | 3.8 | 3/8 |

Select a chain below: