Chain Resources

Contact Us

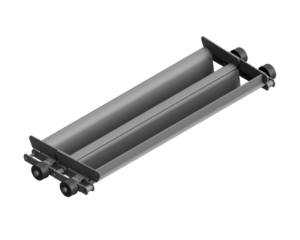

Leakproof Apron Conveyors with

Style C Pans & Outboard Rollers

- Overview

- Material

- Assembly

- Interchangeability

- Application

- Operation

- Specifications

Style A double beaded leakproof pans are recommended for fine or hot materials. The design of the pan holds fine or dry materials until they are discharged. Because the chains are mounted underneath with independent outboard rollers, hot materials can be easily handled.

Pans are mild steel. Sidebars are medium carbon steel. Pins are thru hardened alloy steel for even more wear resistance. Sidebars and pins can be furnished with additional heat treatment on request. Bushings are furnished in case hardened steel to provide maximum wear resistance and chain life. Rollers are furnished in WEBLOY and provide a grease reservoir and lubrication fittings when internal greasing is required.

Apron conveyor chains are cottered construction.

Apron conveyor chains are interchangeable with other standard makes of corresponding sizes and numbers.

Aprons are used in conveyors and feeders where the most difficult operating conditions prevail. The rollers provide lower operating friction which helps to increase chain life and reduce conveyor design requirements.

Apron conveyors are best suited for slow or moderate speed applications. Maximum chain speed depends upon size of sprockets. For Conveyor Service see Table 2, Section A.

Leakproof Apron Conveyors with Style C Pans & Outboard Rollers Product Specifications

Product Information

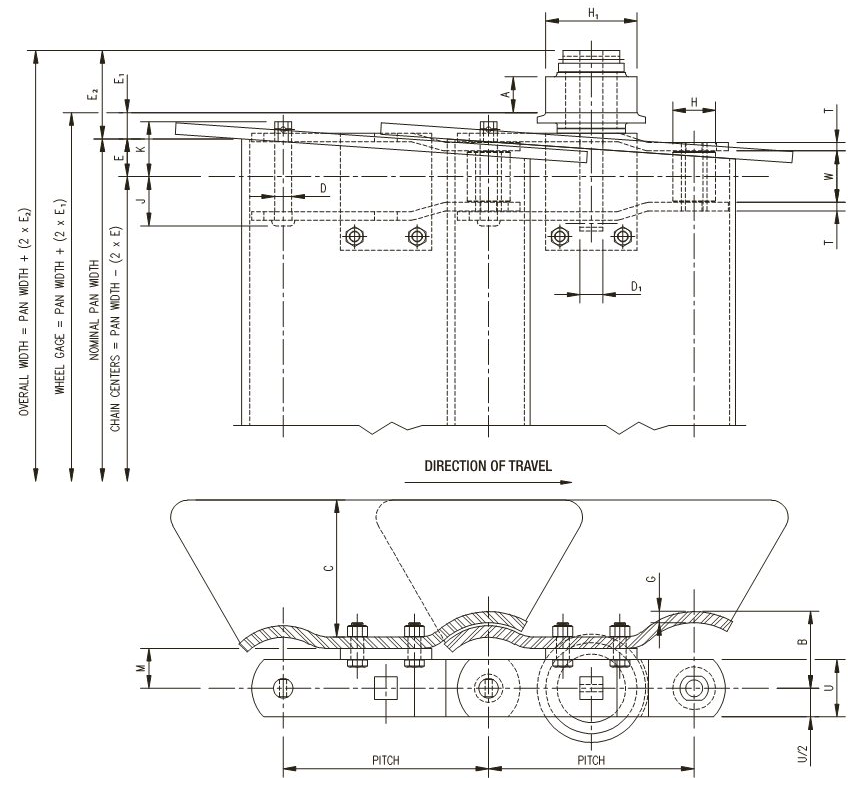

Dimensions are in inches unless otherwise noted.

Dimensions:

Product Chart:

Swipe to See More

| Chain No. | Average Pitch Inches | Average Ultimate Strength in Lbs. Per Strand | Rated Working Load in Lbs. Per Strand | Friction Factor (Fr) | General Dimensions | Pins | Sidebars | Chain Roller Dia. | Outboard Rollers | |||||||||

| Inside Sidebars | To Cotter End | To Head or Rivet End | Dia. | Thk. | Height | Tread Dia. | Tread Width | Stub Shaft | To Inside Pan End | Inside Pan To Wheel Ga. | Inside Pan to Overall Width | |||||||

| Dry | Lubed | W | K | J | D | T | U | H | H1 | A | D1 | E | E1 | E2 | ||||

| SS944+ | 6 | 73,000 | 5,900 | 0.14 | 0.1 | 1 1/2 | 2 1/32 | 1 25/32 | 3/4 | 3/8 | 2 | 1 7/8 | 4 | 1 5/16 | 3/4 | 1 | 1 1/4 | 3 3/8 |

| RS928 | 9 | 50,000 | 7,200 | 0.14 | 0.1 | 2 | 2 9/32 | 2 1/32 | 3/4 | 3/8 | 2 | 1 7/8 | 4 | 1 5/16 | 3/4 | 1 1/4 | 1 1/4 | 3 3/8 |

| RS938 | 9 | 56,000 | 9,200 | 0.14 | 0.1 | 2 1/4 | 2 15/32 | 2 5/32 | 7/8 | 3/8 | 2 1/2 | 1 7/8 | 5 | 1 3/4 | 1 | 1 3/8 | 1 7/16 | 4 1/8 |

| RS946 | 9 | 85,000 | 12,700 | 0.14 | 0.1 | 2 5/8 | 2 27/32 | 2 19/32 | 1 | 1/2 | 2 1/2 | 2 1/4 | 5 | 1 3/4 | 1 | 1 3/16 | 1 7/16 | 4 1/8 |

| RS1228 | 12 | 50,000 | 7,200 | 0.14 | 0.1 | 2 | 2 9/32 | 2 1/32 | 3/4 | 3/8 | 2 | 1 7/8 | 4 | 1 5/16 | 3/4 | 1 1/4 | 1 1/4 | 3 3/8 |

| RS1238 | 12 | 56,000 | 9,200 | 0.14 | 0.1 | 2 1/4 | 2 15/32 | 2 5/32 | 7/8 | 3/8 | 2 1/2 | 1 7/8 | 5 | 1 3/4 | 1 | 1 3/8 | 1 7/16 | 4 1/8 |

| RS1246 | 12 | 125,000 | 12,700 | 0.14 | 0.1 | 2 5/8 | 2 27/32 | 2 19/32 | 1 | 1/2 | 2 1/2 | 2 1/4 | 5 | 1 3/4 | 1 | 1 13/16 | 1 7/16 | 4 1/8 |

| Pan Capacities, Weights and Dimensions | ||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Chain No. | Average Pitch Inches | Capacity | Weight Lbs. Nominal Pan Width = 1'-0" | Add for Each Additional 1'-0" Width in Lbs. | ||||||||||||||

| Dimension C | Dimension C | |||||||||||||||||

| 4 | 5 | 6 | 4 | 5 | 6 | |||||||||||||

| RS1238 | 12 | 23 | 31 | 39 | 119 | 130 | 142 | 40 | ||||||||||

| RS1246 | 12 | 23 | 31 | 39 | 131 | 142 | 154 | 40 | ||||||||||

Dimensions are in inches unless otherwise noted.

Select an attachment below:

Select a chain below: