Vibrating

Equipment

Chain Resources

Contact Us

Flat Spring

Conveyor FSL Models

- Overview

- Material

- Assembly

- Application

- Specifications

All FS conveyors incorporate the natural frequency principle, controlled vibration, positive eccentric drive and standardized sectional construction. They provide a rugged and economical answer to many bulk material conveying and processing jobs.

FS series vibrating conveyors will convey granular or lump material ranging in size from minus 100 mesh to any lump size which will fit into the pan. They can handle weight from several pounds to several hundred pounds per cubic foot, and are particularly effective for conveying heavy, sharp or abrasive materials that are not readily handled on other types of conveyors. They also may be adapted to processing operations, such as inspection, sorting, screening, washing, dewatering, heating, cooling and drying.

Flat Springs

The springs used in the FS series vibrating conveyors are fabricated of a glass filament reinforced plastic which has extremely high flexural strength and excellent resistance to heat, moisture and chemical exposure. These springs are conservatively stressed and will have an extremely long life if the conveyor is properly installed and maintained.

Positive Eccentric Drive

Very little driving force is required when a vibrating conveyor is operating without load and at or close to its natural frequency. The material being conveyed or a buildup of material on the pan will cause significant increases in the driving force required. The positive eccentric drives used in the FS series vibrating conveyors will maintain constant amplitude under the variations in loading which occur in normal operation. These drives are equipped with heavy-duty spherical roller bearings on the eccentric shaft and with a steel encased rubber bushing at the pan end of the connecting rod. This rubber bushing reduces drive forces when starting and stopping, eliminates the need for lubrication at this point and reduces the noise level of the machine. The bearings used are designed so that they cannot be damaged by excessive lubrication.

Standardized Sectional Construction

The FS series vibrating conveyors are standardized sectional conveyors. They are built in 10 foot long sections which are bolted together. Odd length sections are available for use at the ends of the conveyor when the length is not a multiple of 10 feet. The pans are fabricated of mild carbon steel. The thickness and cross-sectional dimensions of the pans for the various standard sections are shown on the following pages. Pans fabricated of other materials or having different dimensions are available.

Unbalanced or Isolated Construction

Standard FS series vibrating conveyors are unbalanced machines and must be installed on a substantial foundation or supporting structure which is usually at or below ground level. If the conveyor is to be installed on an elevated structure, it is desirable to reduce the dynamic reaction transmitted to the supports, it may be equipped with a heavy inertia base and soft isolating springs. This type of construction will reduce the forces transmitted to the support by 85% to 95%. Standard and High Temperature Construction Webster FS series vibrating conveyors are available in two types and the selection of the proper type is dependent on the temperature of the material being conveyed. When material temperature is no higher than 150° to 200° F, standard or nonexpansion construction is used. For hotter materials high temperature or heat expansion construction can be used, or a switch to CoilWeb® series may be recommended. The high temperature type is designed so the pan is free to expand and contract and warpage is controlled. Air-oil mist type lubrication is available if required for hot, humid or very dirty environments.

| Model | Standard Construction | Heat-Expansion Construction |

| FSL | 150 F | CoilWeb |

| FSM | 150 F | CoilWeb |

| FSh | 150F | CoilWeb |

| CoilWeb | 200 F | 800 F |

Accessories

A wide range of optional features are available for use with FS series vibrating conveyors. Included are covers, side or bottom discharges, intermediate discharges with gates, pans with multiple compartments or channels, screen sections, nonmagnetic pan sections for use with magnetic separators, nonmetallic pan sections for use with metal detectors, steel pan liners for impact or abrasion resistance, rubber pan liners for wear resistance or noise reduction, special discharges for feeding process equipment and steel support structures.

The FS series vibrating conveyors incorporate fabricated steel pans, a natural frequency spring system, a positive eccentric drive powered by an electric motor and v-belts on a fabricated steel base.

Standard drive and extension sections are delivered in preassembled sections. Jig fixtured, bolted pan flanges make field assembly easy.

FS series vibrating conveyors are used where horizontal or shallow inclined conveying is required. They handle a wide variety of bulk materials from powders to solids. They are well suited to handle fragile, sharp and irregularly shaped materials. They are primarily used in the forest products, stamping, food, grain and chemical industries.

Flat Spring Conveyor FSL Models Product Specifications

Product Information

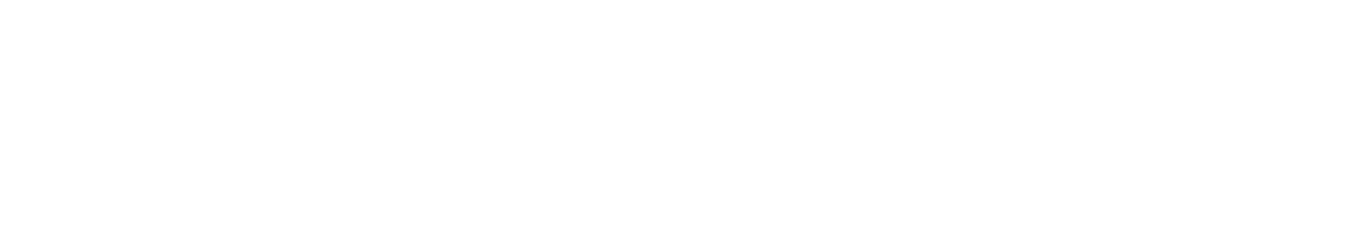

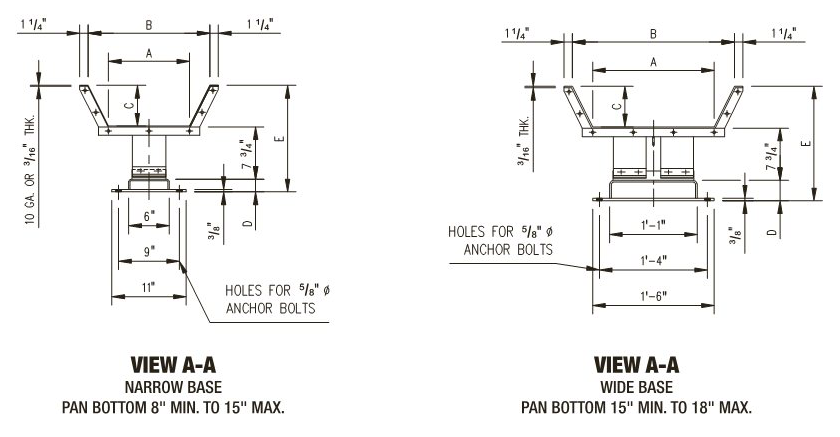

Dimensions are in inches unless otherwise noted.

Dimensions:

Product Chart:

Swipe to See More

| FSL Cross Section Dimensions | ||||||

| Pan Size | A | B | C | D | E | Base |

| 12/16 | 12" | 16" | 4" | 1 7/8" | 1'-1 3/4" | Narrow |

| 12/18 | 12" | 18" | 6" | 1 7/8" | 1'-3 3/4" | Narrow |

| 18/22 | 18" | 22" | 4" | 3" | 1'-2 15/16" | Wide |

| 18/24 | 18" | 24" | 6" | 3" | 1'-4 15/16" | Wide |

Dimensions are in inches unless otherwise noted.

Select an attachment below:

Select a chain below: