Pulp

& Paper

Chain Resources

Contact Us

Our Products Used in the Pulp & Paper Industry

Wood is the raw material that is used to produce pulp, paper, paperboard and other cellulose-based products. The transfer of raw materials requires a durable, consistent and reliable conveying components. Webster provides this industry with a variety of products to fit any customer’s application.

Pulp & paper industry chains and conveyors include:

• Apron Conveyors

• Welded Steel Mill Chains

• Welded Steel Drag Chains

• Steel Bushed Roller Chains

• Cast Chains

• FS Series Vibrating Conveyors

• ACTION Vibrating Conveyors

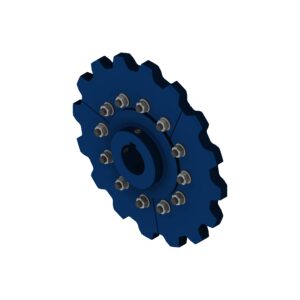

• Sprockets

Chain Products

Apron Conveyors

Apron conveyors are engineered to handle a variety of materials ranging from hot and abrasive to dry and fine.

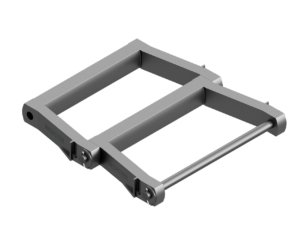

Welded Steel Heavy-Duty Drag Chains

Welded steel heavy-duty drag chains are manufactured with larger, heftier parts with extra surface area for longer service life. Their rugged welded construction permits higher speeds, minimal lubrication and easy modification for application specific attachments.

Welded Steel Mill Chains

Welded steel mill chains are designed for rugged, abrasive and demanding environments.

Metrics OEM Replacement Chains

Webster has the unique capability to retrofit most competitive, existing metric size floating attachment, central bucket elevator chains. Our chains are designed to fit into the existing OEM application, allowing the end user to utilize the same bucket punch hole sizes and locations, as well as run on the same traction wheels or sprockets.

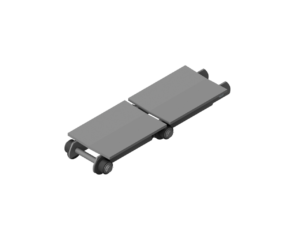

Gull Wing Conveyor Chains - Paper Rolls

Gull wing conveyor chains with V-shaped top plates are used almost exclusively to handle paper rolls. The outboard rollers have a wider wheel gauge and provide more stability for the rolls.

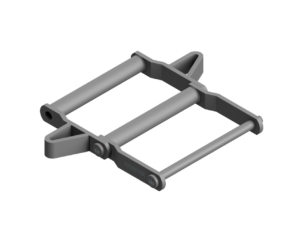

Welded Steel Drag Chains

Welded steel drag chains are designed for drag conveyors where r ugged and demanding environments exist. Webster’s unique two-piece welded barrel offers better scraping action as well as double thickness at the wear points. The rugged welded construction permits high speeds, minimal lubrication and easy modification for application specific attachments.

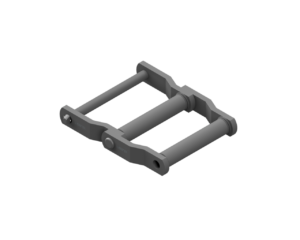

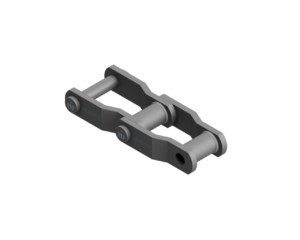

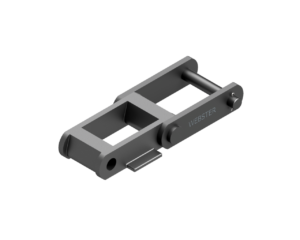

Steel Bushed Roller (SBR) Chains

Steel bushed roller (SBR) chains are manufactured with heat treated rollers, hardened bushings and pins, and steel sidebars. The roller type construction provides a lower operating friction which helps increase chain life and reduces conveyor design requirements. They are available in a variety of sizes, configurations and designs and can be used in tough industrial applications. SBR chains come with a variety of standard attachments for immediate delivery.

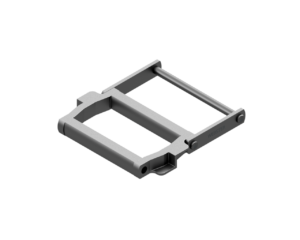

WS and DW Combination Chains

WS and DW combination chains have block links that are designed to provide extra wear surfaces for sliding on both the carrying and return runs of wood yard conveyors. This makes it possible to eliminate the return idler sprockets which cause internal wear of the chain parts.

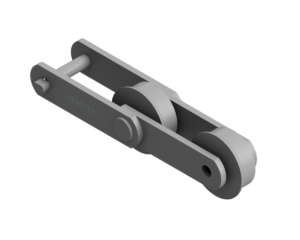

Combination Rooftop Transfer Chain

Combination rooftop transfer chain is used chiefly in two or more strands on transfer conveyors handling lumber, boxes, packages, barrels, bars, etc. Only the bevel tops of the links project about the guides, permitting loading and unloading to be done transversely.

Rooftop Transfer Chains

Rooftop transfer chain is used chiefly in two or more stands on transfer conveyors handling lumber, boxes, packages, barrels, bars, etc. Only the bevel tops of the links project about the guides, permitting loading and unloading to be done transversely.

Combination Type Drag Chain

Combination type drag chains are designed with sections heavier than comparable sizes of H type drag chains. The double offset wear shoes on the cast link provide wear surfaces for both carrying and return runs, thus increasing chain life.

H Type Drag Chains

H type drag chains have links designed to operate in troughs or runways, in single or multiple strands. The underside of the links are broad to provide liberal wear surface. They are designed for heavy-duty operation imposed by drag conveyor service such as moving sawdust, refuse, fine coal, ash and other material in places where an economical installation is required.

400 Class Pintle Chains

400 class pintle chains are of one-piece cast offset link construction joined together by steel pins. When furnished with attachments, they are normally used for conveyors and elevators where much slower speeds are recommended.