Grain

Chain Resources

Contact Us

Our Products Used in the Grain Industry

Webster inventories every common engineered chain used in the grain market and can custom produce an application specific product in very short lead-times to find the best product for the right application. Enmasse drag conveyors utilize these chains with flights for conveying products, quickly, effectively and safely in grain processing. Additionally, Webster can design a chain and/or bucket combination specifically suited for your particular application.

Grain industry chains and conveyors include:

• Welded Steel Mill Chains

• Welded Stainless Steel Mill Chains

• Steel Bushed Roller Chains

• Hardened Steel Bushed Chains

• Combination Chains

• FS Series Vibrating Conveyors

• ACTION Vibrating Conveyors

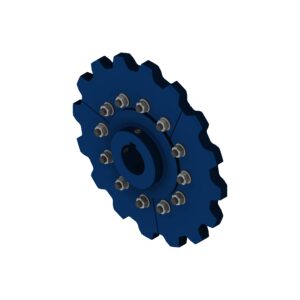

• Sprockets

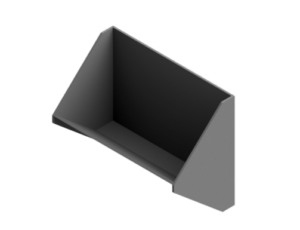

• Buckets

Chain Products

Welded Steel Mill Chains

Welded steel mill chains are designed for rugged, abrasive and demanding environments.

Welded Stainless Steel Mill Chains

Welded stainless steel mill chains are designed for highly corrosive conditions often found in the ethanol, grain, paper, dairy, sugar, food processing, brewing, petroleum and chemical industries. The Type 316L stainless steel sidebars and Type 17-4 PH pins and barrels provide greater wearability and corrosion resistance. The Type 316L stainless steel sidebars have excellent welding characteristics.

Hardened Steel Bushed (HSB) Chains

Hardened steel bushed (HSB) chains are designed as a substitute for combination chains where conditions require a heavier, more rugged chain.

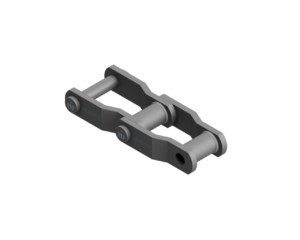

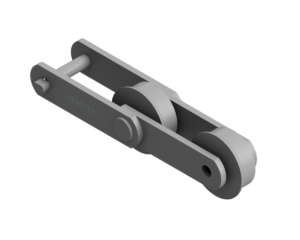

Steel Bushed Roller (SBR) Chains

Steel bushed roller (SBR) chains are manufactured with heat treated rollers, hardened bushings and pins, and steel sidebars. The roller type construction provides a lower operating friction which helps increase chain life and reduces conveyor design requirements. They are available in a variety of sizes, configurations and designs and can be used in tough industrial applications. SBR chains come with a variety of standard attachments for immediate delivery.

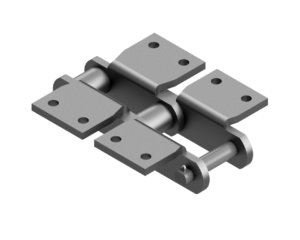

Combination Chains

Combination chains are made of cast block links and steel sidebars alternately spaced. The N combination chains have pear-shaped barrels to provide additional metal where the chain engages the sprocket teeth to increase the service life of the chain. Combination chains are well suited for abrasive, gritty or corrosive materials and are a less expensive option to their all steel counterparts (HSB).