Stamping

Chain Resources

Contact Us

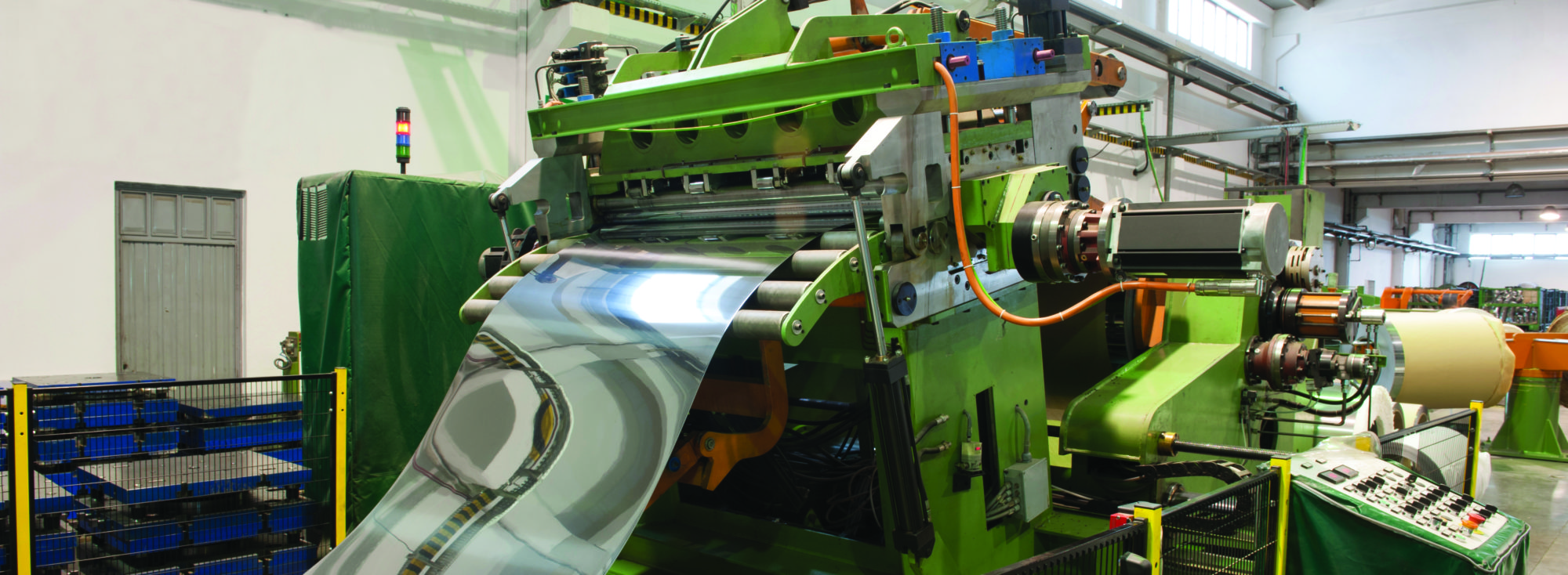

Our Products Used in the Stamping Industry

The stamping process is prevalent in the automotive and steel industries. The shearing, bending and dyeing of metal creates a demanding and abrasive environment for any conveyor. Webster conveyors are engineered to transport discharged scrap material of various sizes and weight, while tolerating harsh conditions. Our dimpled pan construction allows for the oily material to be discharged properly.

Stamping industry conveyors include:

• ENDURO-FLITE® Conveyors

• Apron Conveyors

• FS Series Vibrating Conveyors

• ACTION Vibrating Conveyors

• Sprockets

Chain Products

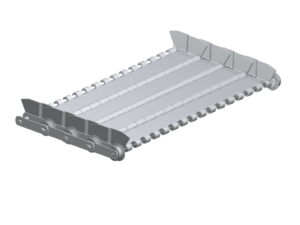

Apron Conveyors

Apron conveyors are engineered to handle a variety of materials ranging from hot and abrasive to dry and fine.

ENDURO-FLITE®

ENDURO-FLITE® is made with SBR chains, alloy steel thru rods, inner tubes and formed or welded hinge steel pans. This light to medium duty apron is available in 6″, 9″ or 12″ pitch with pan widths from 12″ to 120″. Side wings are welded to the pan which makes it ideal for the recycling and stamping industries. Numerous attachments available for specific application needs.