Sprockets

Chain Resources

Contact Us

Sprockets

Webster Sprockets are designed and manufactured according to the same core quality standards as Webster chain. Each sprocket is carefully designed by Webster’s experienced engineering team, and is then manufactured with the highest quality USA made medium carbon steel by skilled American laborers.

Pairing Webster Chain and Sprockets on your application, ensures that your conveyor is performing at the highest level of productivity, reliability and service.

Webster sprockets are designed and manufactured per the ASME/ANSI specifications. The sprocket selection and design depend on the customers application. However, Webster standard sprockets design to effective operation of engineered class chain. Webster’s standard design utilizes low profile teeth to ensure the sprocket does not interfere with the chain and its attachments. High profile or customized teeth are available. Please consult our engineering department for any special needs.

Designs and special features include:

- Standard – solid, split or segmented construction

- Traction Wheel

- Drum Sprocket

- Flanged Rim Drum Sprocket

- Hunting (Walking) Tooth Sprocket

- Chain Saver Sprocket

- Gap Tooth Sprocket

- Mud Relief Sprocket

- Chain Saver Sprocket

- Clinker Drag Chain Sprocket

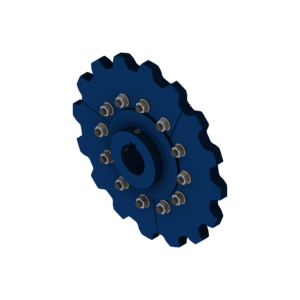

Our Sprockets

Cast Iron Chilled Rim Sprockets

Cast iron chilled rim sprockets and traction wheels have smooth, hard, iron wear surfaces. These sprockets are especially well suited for applications handling abrasive materials such as sand, gravel, ash or cement.

Flame Cut Hardened Sprockets

Flame Cut Flame Hardened sprockets and traction wheels are used for extremely abrasive applications with high shock loading. The inherent strength and flame hardened teeth of these sprockets provide maximum service in the most severe environments. The versatility of flame cut sprockets allows for specialized designs for a variety of customer requirements.