Engineered

Class Chains

Chain Resources

Contact Us

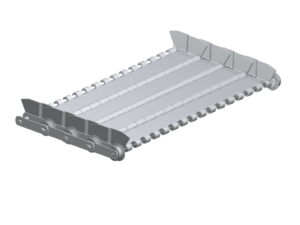

ENDURO-FLITE®

- Overview

- Material

- Assembly

- Interchangeability

- Application

- Operation

- Specifications

For light to medium-duty applications, Webster offers our piano hinge apron conveyor which carries the registered trademark ENDURO-FLITE®. Webster is the only chain manufacturer producing the formed piano hinge design. Due to our extensive background in chain design we understand the importance of controlling pitch tolerance and hole quality. ENDURO-FLITE® components share both load and wear factors evenly, providing trouble free service to your material handling operation. ENDURO-FLITE® is available with formed hinges in both 6″ and 9″ pitch and with welded hinges in 12″ pitch.

Industries

Pans and wings are mild steel. Sidebars are medium carbon steel. Thru rods are alloy steel. Bushings are furnished in case hardened steel to provide maximum wear resistance and chain life. Rollers are WEBLOY for increased life. Rollers can also be furnished in Duramal with needle bearings to reduce friction and further extend chain life.

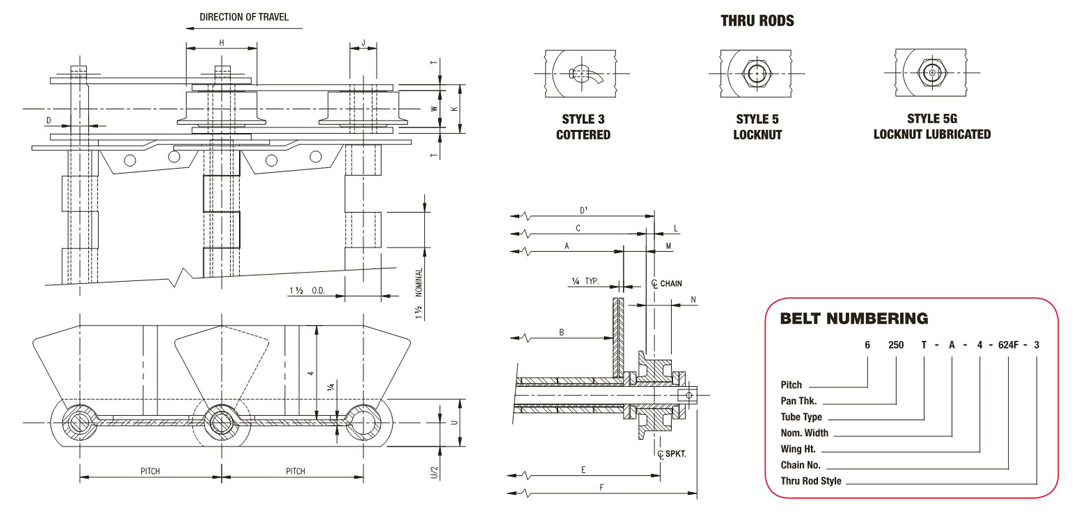

ENDURO-FLITE® conveyors are cottered construction. Thru rods are also available threaded with locknuts as well as drilled for lubrication.

ENDURO-FLITE® chain components, pans and wings are fully interchangeable with other standard makes of corresponding sizes and numbers.

ENDURO-FLITE® conveyors are used in stamping plants, recycling facilities and other industries where a lightweight, yet rugged, conveyor is required. Pans can be furnished dimpled, perforated or both for applications where a nonstick surface or drainage is needed.

ENDURO-FLITE® conveyors are best suited for slow or moderate speed applications. Maximum chain speed depends upon size of sprockets. For Conveyor Service see Table 2, Section A.

ENDURO-FLITE® Product Specifications

Product Information

Dimensions are in inches unless otherwise noted.

Dimensions:

Product Chart:

Swipe to See More

| Chain No. | 614P | 624F | 625F | 634F | 635F | 914P | 924F | 925F | 934F | 935F |

| A - Pan Width | 12" to 96" Wide | |||||||||

| B - Inside Wings (3⁄16" Thick) | A - 13⁄16 | A - 13⁄16 | A - 13⁄16 | A - 13⁄16 | A - 13⁄16 | A - 13⁄16 | A - 13⁄16 | A - 13⁄16 | A - 13⁄16 | A - 13⁄16 |

| B - Inside Wings (1⁄4" Thick) | A - 1 1⁄16 | A - 1 1 ⁄16 | A - 1 1⁄16 | A - 1 1⁄16 | A - 1 1⁄16 | A - 1 1⁄16 | A - 1 1⁄16 | A - 1 1⁄16 | A - 1 1⁄16 | A - 1 1⁄16 |

| C - Roller Gage | N/A | A + 1 15⁄16 | A + 1 15⁄16 | A + 2 11⁄16 | A + 2 11⁄16 | N/A | A + 1 15⁄16 | A + 1 15⁄16 | A + 2 11⁄16 | A + 2 11⁄16 |

| D¹ - Chain Centers | A + 2 5⁄16 | A + 2 5⁄8 | A + 2 5⁄8 | A + 3 9⁄16 | A + 3 9⁄16 | A + 2 5⁄16 | A + 2 5⁄8 | A + 2 5⁄8 | A + 3 9⁄16 | A + 3 9⁄16 |

| E - Sprocket Centers | A + 2 5⁄16 | A + 3 | A + 3 | A + 4 | A + 4 | A + 2 5⁄16 | A + 3 | A + 3 | A + 4 | A + 4 |

| F - Overall Width | A + 5 3⁄8 | A + 6 1⁄4 | A + 6 1⁄4 | A + 8 1⁄8 | A + 8 1⁄8 | A + 5 3⁄8 | A + 6 1⁄4 | A + 6 1⁄4 | A + 8 1⁄8 | A + 8 1⁄8 |

| Weight (Lbs./Ft.) 4" Wings (3⁄16" Thick) | 24.5 + (A x 1.35) | 27.5 + (A x 1.35) | 27.5 + (A x 1.35) | 46.5 + (A x 1.35) | 46.5 + (A x 1.35) | 20.5 + (A x 1.35) | 22.5 + (A x 1.35) | 22.5 + (A x 1.35) | 35.5 + (A x 1.35) | 35.5 + (A x 1.35) |

| Weight (Lbs./Ft.) 4" Wings (1⁄4" Thick) | 27 + (A x 1.35) | 30 + (A x 1.35) | 30 + (A x 1.35) | 49 + (A x 1.35) | 49 + (A x 1.35) | 23 + (A x 1.35) | 25 + (A x 1.35) | 25 + (A x 1.35) | 38 + (A x 1.35) | 38 + (A x 1.35) |

| Weight (Lbs./Ft.) 6" Wings (3⁄16" Thick) | - | - | - | - | - | 25.5 + (A x 1.35) | 26.5 + (A x 1.35) | 26.5 + (A x 1.35) | 40.5 + (A x 1.35) | 40.5 + (A x 1.35) |

| Weight (Lbs./Ft.) 6" Wings (1⁄4" Thick) | - | - | - | - | - | 29 + (A x 1.35) | 31 + (A x 1.35) | 31 + (A x 1.35) | 44 + (A x 1.35) | 44 + (A x 1.35) |

| Inner Tube | .970 O.D. x .780 I.D | |||||||||

| Min. Reflex Radius 4" Wings | 36" | 30" | ||||||||

| Min. Reflex Radius 6" Wings | - | - | - | - | - | 42" | ||||

Dimensions are in inches unless otherwise noted.

Select an attachment below:

Select a chain below: