Engineered

Class Chains

Chain Resources

Contact Us

Flat & Slat

Top Conveyor Chains

- Overview

- Material

- Assembly

- Interchangeability

- Application

- Operation

- Specifications

Flat and slat top conveyor chains are typically designed with a flat steel top plate either welded (flat top) or bolted (slat top) to an SBR chain. Outboard rollers with bearings are added to reduce rolling friction. The top plate surface provides excellent floor level conveying. Flat and slat top conveyors are used widely in the automotive industry for final assembly, mechanical or paint repair and water test or wash applications. These chains can be custom designed for your specific application needs.

Industries

Top plates are mild steel. Sidebars are medium carbon steel. Thru rods are cold finished alloy steel. Inboard bushings and rollers and outboard bushings are carburized to provide maximum wear resistance and service life. Outboard rollers are furnished in various configurations of bearings, materials and heat treatment as shown below. Flat top chains can be furnished in stainless steel with UHMW outboard rollers for wet applications.

Flat top conveyor chains are cottered construction.

Flat top conveyor chains are made to order. However, chains used in the automotive industry are designed in accordance with the automaker’s specifications and are interchangeable with other manufacturers.

Flat top conveyor chains are primarily used for handling automobiles or paper rolls. Typically the conveyors are long and handling large or heavy loads requiring a heavy-duty chain as well as reduced rolling friction in the outboard rollers.

Flat top conveyor chains are best suited for slow speed applications. Eight tooth sprockets are most common with these chains. For Conveyor Service see Table 2, Section A.

Flat & Slat Top Conveyor Chains Product Specifications

Product Information

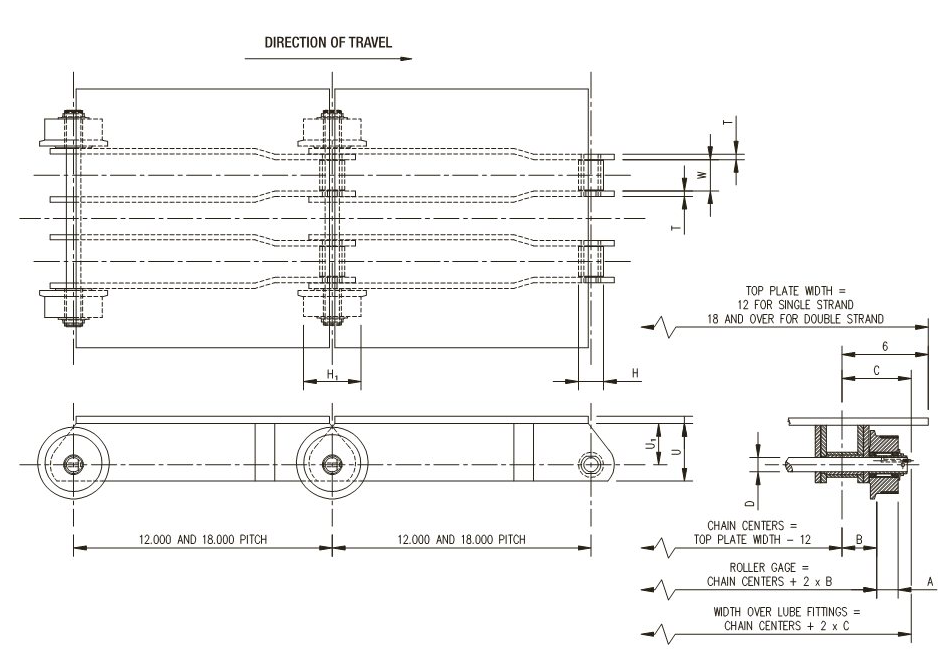

Dimensions are in inches unless otherwise noted.

Dimensions:

Product Chart:

Swipe to See More

| Average Ultimate Strength in Lbs. | Rated Working Load in Lbs. | Max Load Per Outboard Roller | General Dimensions | Pins | Sidebars | Rollers | ||||||

| Inside Sidebars | Chain To Roller Ga. | Chain To Overall Width | Dia. | Thk. | Height | To Top Plate | Inboard Dia. | Outboard Dia. | Outboard Tread Width | |||

| W | B | C | D | T | U | U1 | H | H1 | A | |||

| 64,000 | 8,230 | 3,500 | 1 15⁄16 | 2 5⁄16 | 4 5⁄8 | 7⁄8 | 3⁄8 | 3 1⁄2 | 2 3⁄8 | 1 3⁄4 | 3 | 1 3⁄8 |

| 4 | 2 7⁄8 | 4 | ||||||||||

| 61,000 | 8,750 | 5,000 | 1 3⁄4 | 2 1⁄4 | 4 9⁄16 | 1 | 3⁄8 | 3 1⁄2 | 2 1⁄4 | 1 3⁄4 | 3 | 1 3⁄8 |

| 4 | 2 3⁄4 | 4 | ||||||||||

| 56,000 | 9,400 | 5,000 | 1 15⁄16 | 2 3⁄8 | 4 25⁄32 | 1 | 3⁄8 | 4 | 2 7⁄8 | 1 7⁄8 | 4 | 1 1⁄2 |

| 85,000 | 12,850 | 7,500 | 1 15⁄16 | 2 9⁄16 | 5 | 1 1⁄4 | 1⁄2 | 4 | 2 11⁄16 | 2 1⁄4 | 4 | 1 17⁄32 |

Dimensions are in inches unless otherwise noted.

Select an attachment below:

Select a chain below: