Engineered

Class Chains

Chain Resources

Contact Us

H Class

Mill Chains

- Overview

- Material

- Assembly

- Interchangeability

- Application

- Operation

- Specifications

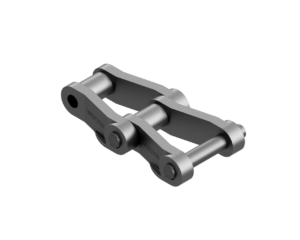

H class mill chains are of one-piece cast offset link construction joined together by steel clipped heads. They are used primarily for drag conveyor service in the lumber, pulp and paper industries. They are also desirable for transfer and conveying purposes.

Links are cast of high grade copper bearing malleable iron or Duramal. Duramal is a heat treated malleable iron having greater strength and superior resistance to wear and abrasion. Duramal chains have heat treated pins.

Riveted construction is furnished unless cottered construction is requested.

H class mill chains are interchangeable with other standard makes of corresponding sizes and numbers.

H class mill chains are used primarily for drag conveyor service in the lumber, pulp and paper industries. They are also desirable for transfer and conveying purposes. The pin joint permits operation in a moderately dusty or abrasive atmosphere.

The maximum speed of this chain is generally 450 FPM, but depends upon size of sprockets. For Drive Service see Table 10, Section A. For Conveyor Service see Table 2, Section A.

H Class Mill Chains Product Specifications

Product Information

Dimensions are in inches unless otherwise noted.

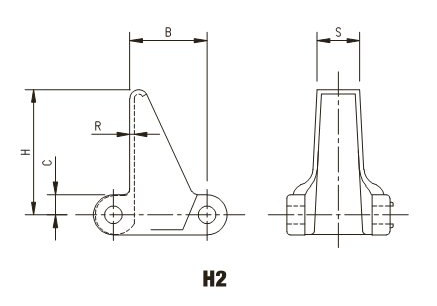

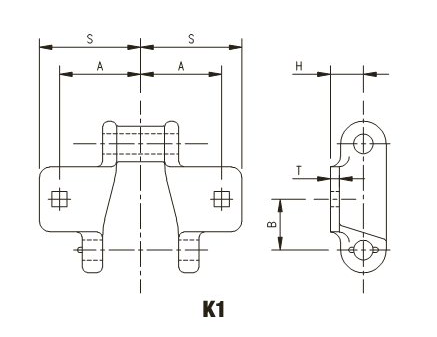

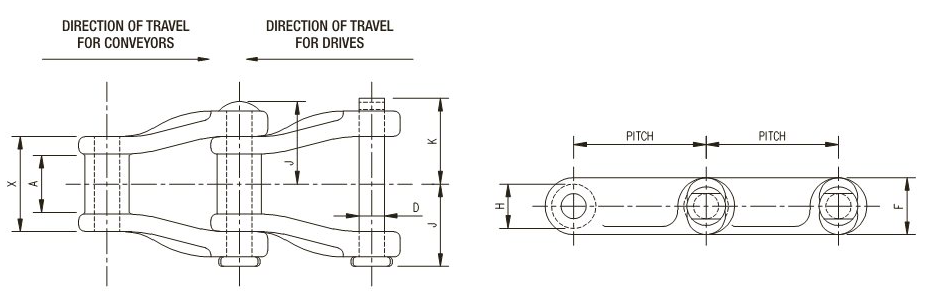

Dimensions:

Product Chart:

Swipe to See More

| Chain No. | Dimensions in Inches | Attachment Numbers | |||||||||||||

| Average Pitch Inches | Approx. Links in 10 feet | Average Weight Per Ft. Lbs. | Average Ultimate Strength in Lbs. | Rated Working Load in Lbs. | Barrel Length | Sidebar Width | Max. Spkt. Width | Pin Dia. | Barrel Dia. | To Cotter End | To Head or Rivet End | ||||

| Malleable | Duramal | Malleable | Duramal | X | F | A | D | H | K | J | |||||

| H60 | 2.308 | 52 | 2.1 | 7,000 | 8,750 | 1,170 | 1,400 | 1 1⁄2 | 3⁄4 | 3⁄4 | 5⁄16 | 3⁄4 | 1 7⁄16 | 1 3⁄8 | F4, H2, K1, RR |

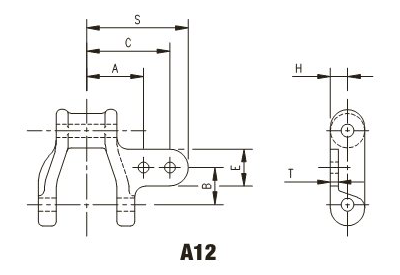

| H62 | 1.654 | 73 | 2.4 | 7,000 | 8,750 | 1,030 | 1,235 | 1 5⁄16 | 13⁄16 | 7⁄8 | 5⁄16 | 13⁄16 | 1 1⁄8 | 1 3⁄32 | A12 |

| H74 | 2.609 | 46 | 3.0 | 10,000 | 12,500 | 1,525 | 1,830 | 1 5⁄8 | 1 | 1 | 3⁄8 | 7⁄8 | 1 9⁄16 | 1 7⁄16 | F4, H2, K1, R1 |

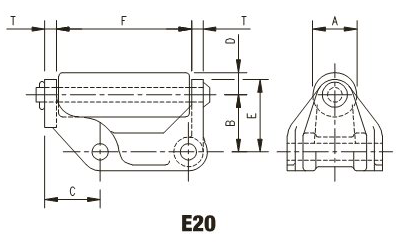

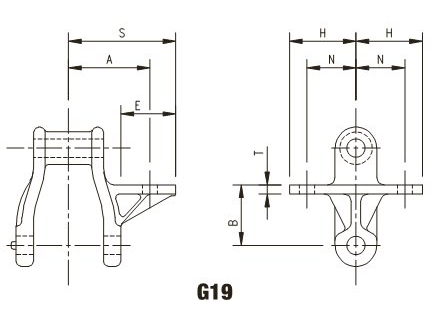

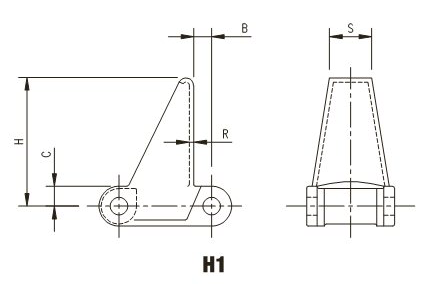

| H78 | 2.609 | 46 | 4.2 | 16,000 | 20,000 | 2,340 | 2,810 | 1 7⁄8 | 1 1⁄8 | 1 1⁄8 | 1⁄2 | 7⁄8 | 1 21⁄32 | 1 19⁄32 | E20, F4, G19, H1, H2, K1, K2, R1, RR |

| H82 | 3.075 | 39 | 5.5 | 20,000 | 25,000 | 3,080 | 3,695 | 2 3⁄16 | 1 1⁄4 | 1 1⁄4 | 9⁄16 | 1 7⁄32 | 2 1⁄16 | 1 7⁄8 | F4, H2, K1, K2, M1 |

| H85 | 4.000 | 30 | 3.3 | 12,500 | 15,625 | 2,080 | 2,600 | 2 5⁄8 | 1 | 1 7⁄8 | 7⁄16 | 31⁄32 | 2 | 1 15⁄16 | |

| H124 | 4.000 | 30 | 8.8 | 30,000 | 37,500 | 5,000 | 6,000 | 2 3⁄4 | 1 9⁄16 | 1 5⁄8 | 3⁄4 | 1 7⁄16 | 2 7⁄16 | 2 1⁄4 | F4, K1 |

Dimensions are in inches unless otherwise noted.

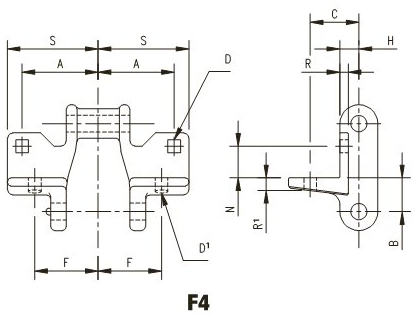

Select an attachment below:

Click to view 3D

Click to view 3D

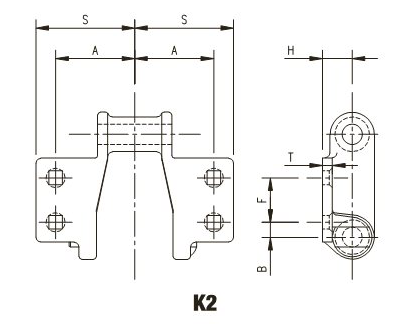

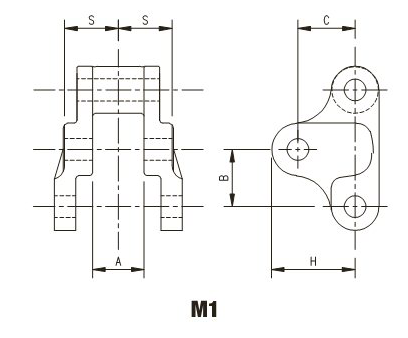

| Chain No. | A | B | C | F | H | N | R | R1 | S | Weight Per Foot-Lbs. | Bolt Size D | Bolt Size D |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| H60 | 1 31⁄32 | 7⁄8 | 1 1⁄4 | 1 17⁄32 | 3⁄8 | 3⁄4 | 3⁄16 | 5⁄16 | 2 3⁄8 | 4.7 | 3⁄8 | 3⁄8 |

| H74 | 2 1⁄16 | 1 3⁄16 | 1 7⁄16 | 1 5⁄8 | 1⁄2 | 5⁄8 | 1⁄4 | 3⁄8 | 2 7⁄16 | 6.0 | 5⁄16 | 3⁄8 |

| H78 | 2 1⁄4 | 1 | 1 7⁄16 | 1 7⁄8 | 9⁄16 | 15⁄16 | 1⁄4 | 3⁄8 | 2 11⁄16 | 8.1 | 3⁄8 | 3⁄8 |

| H82 | 2 1⁄2 | 1 1⁄4 | 1 1⁄2 | 2 1⁄16 | 5⁄8 | 7⁄8 | 9⁄32 | 3⁄8 | 3 | 8.9 | 3⁄8 | 3⁄8 |

| H124 | 2 21⁄32 | 1 1⁄2 | 1 5⁄8 | 2 3⁄16 | 13⁄16 | 1 1⁄16 | 9⁄32 | 1⁄2 | 3 1⁄8 | 11.8 | 3⁄8 | 3⁄8 |

Select a chain below: